Technical Services (performed by ORNL's Stable Isotope Group)

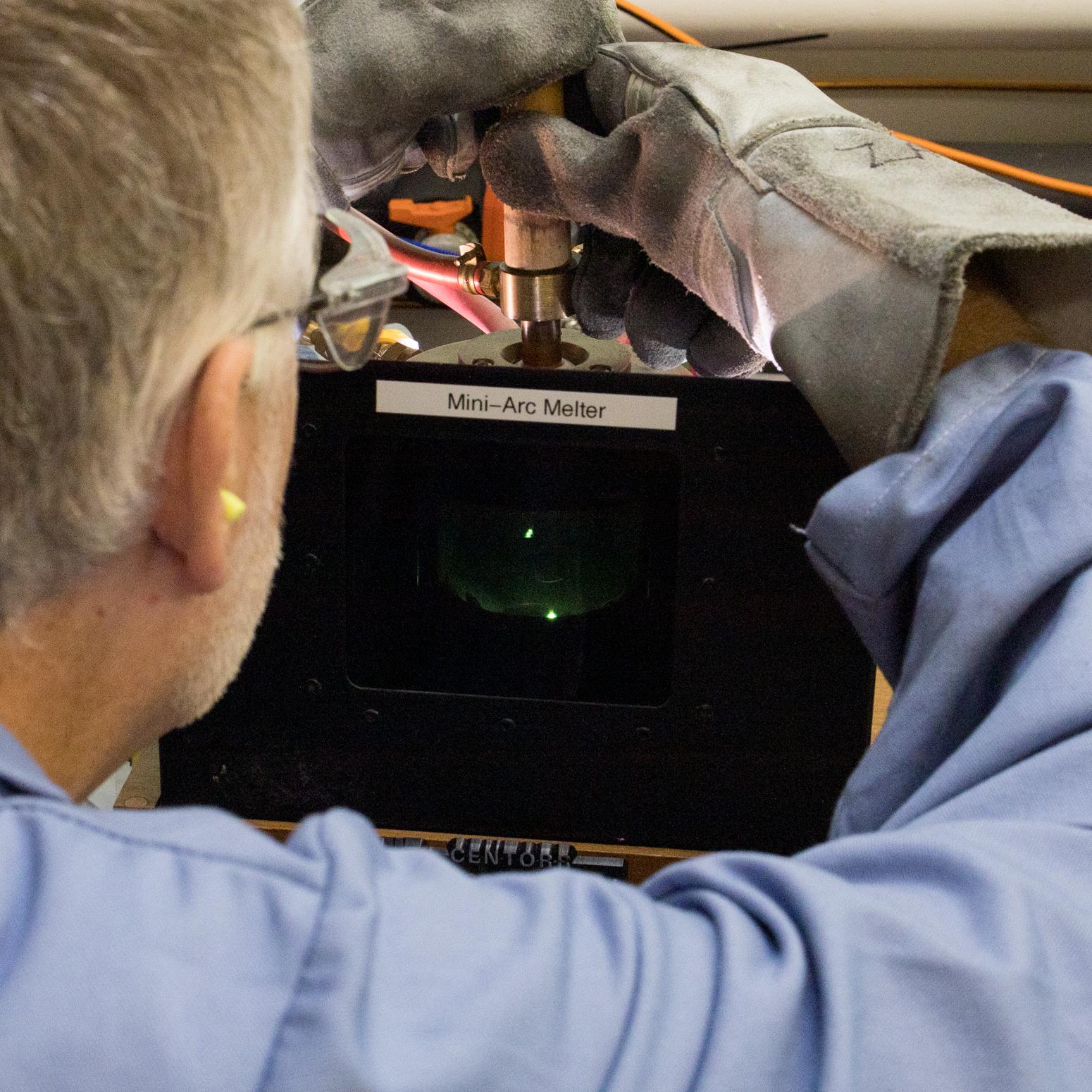

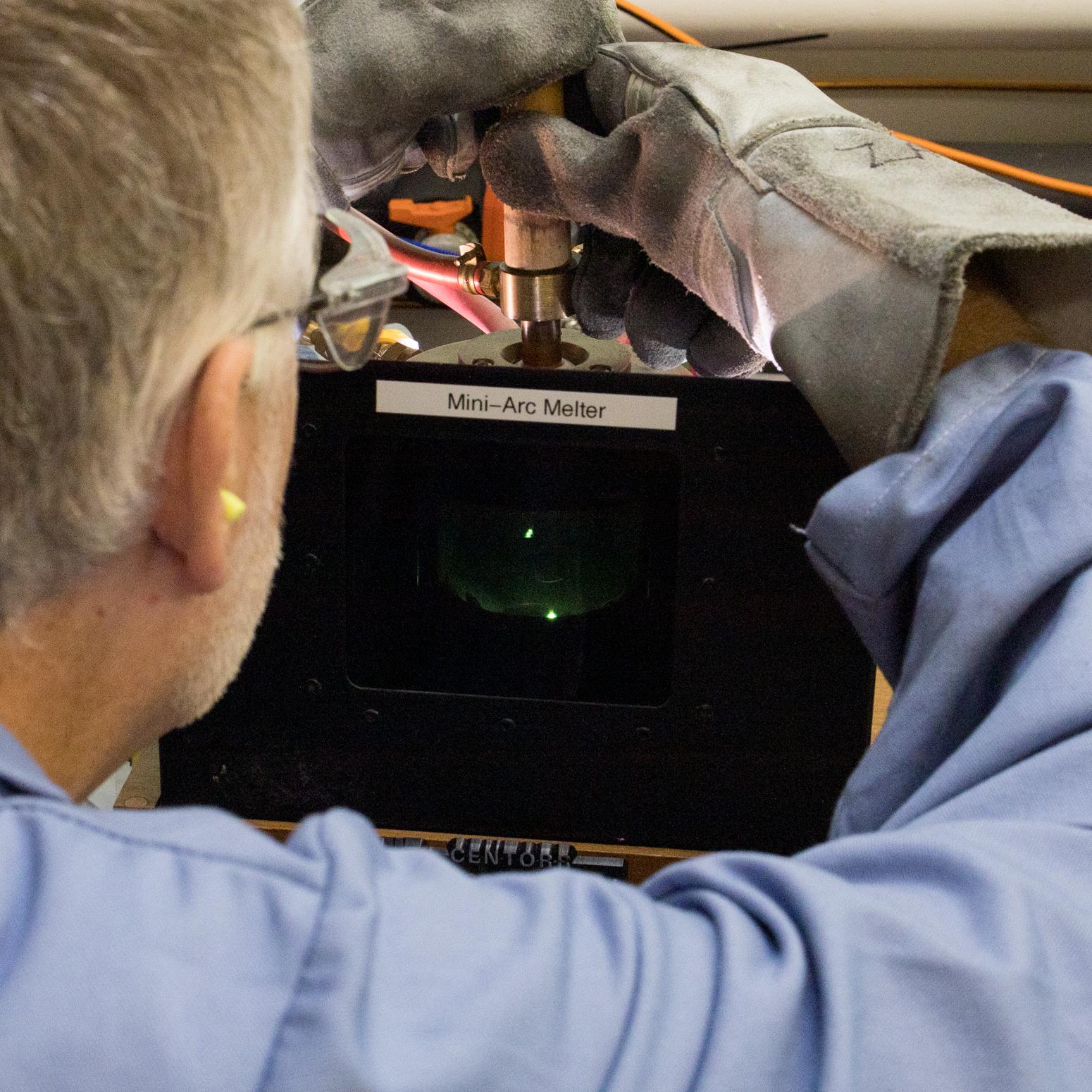

Arc melting, casting, alloying, and drop casting

Techniques used for the preparation of metal ingots and reclamation materials, such as foil trimmings, for further processing

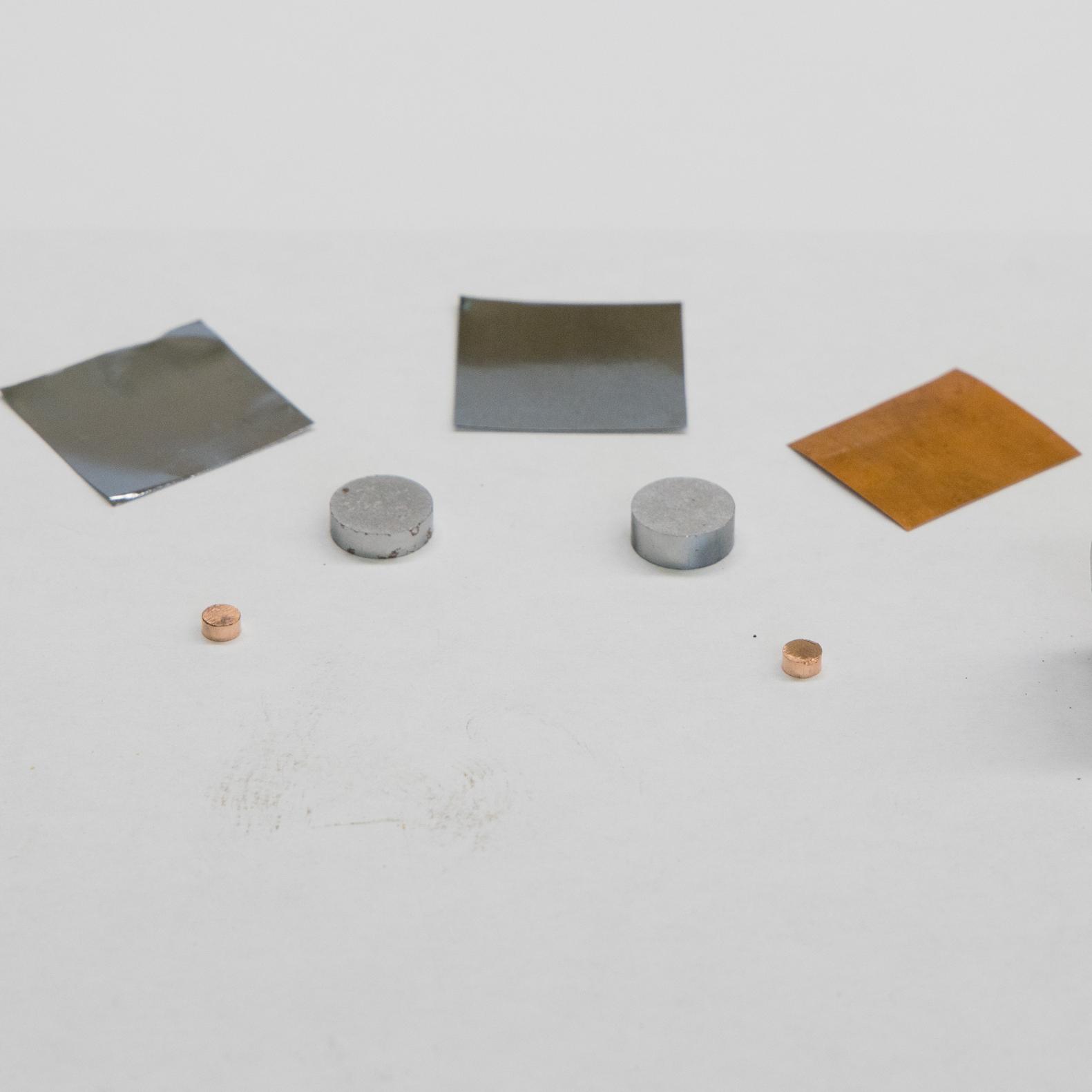

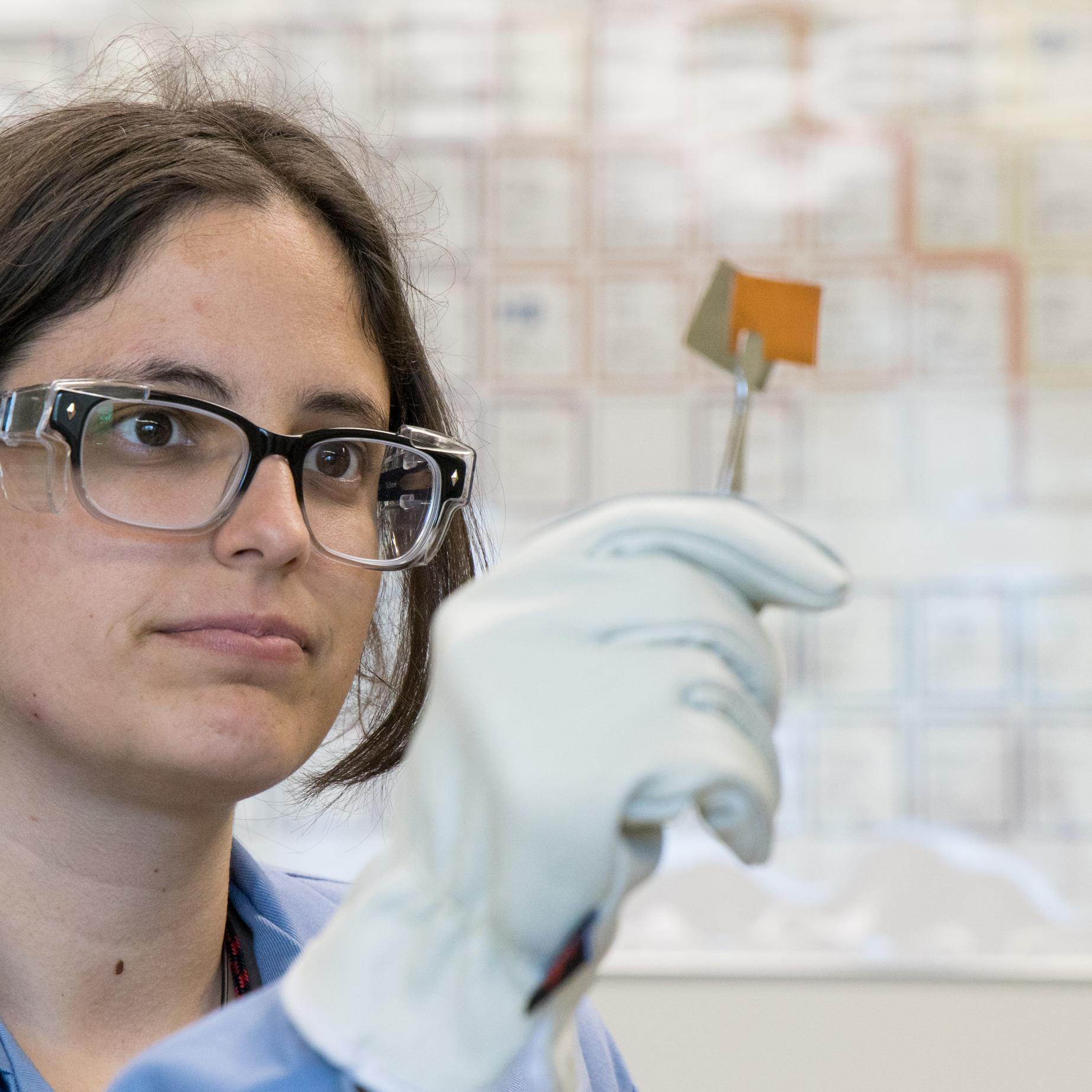

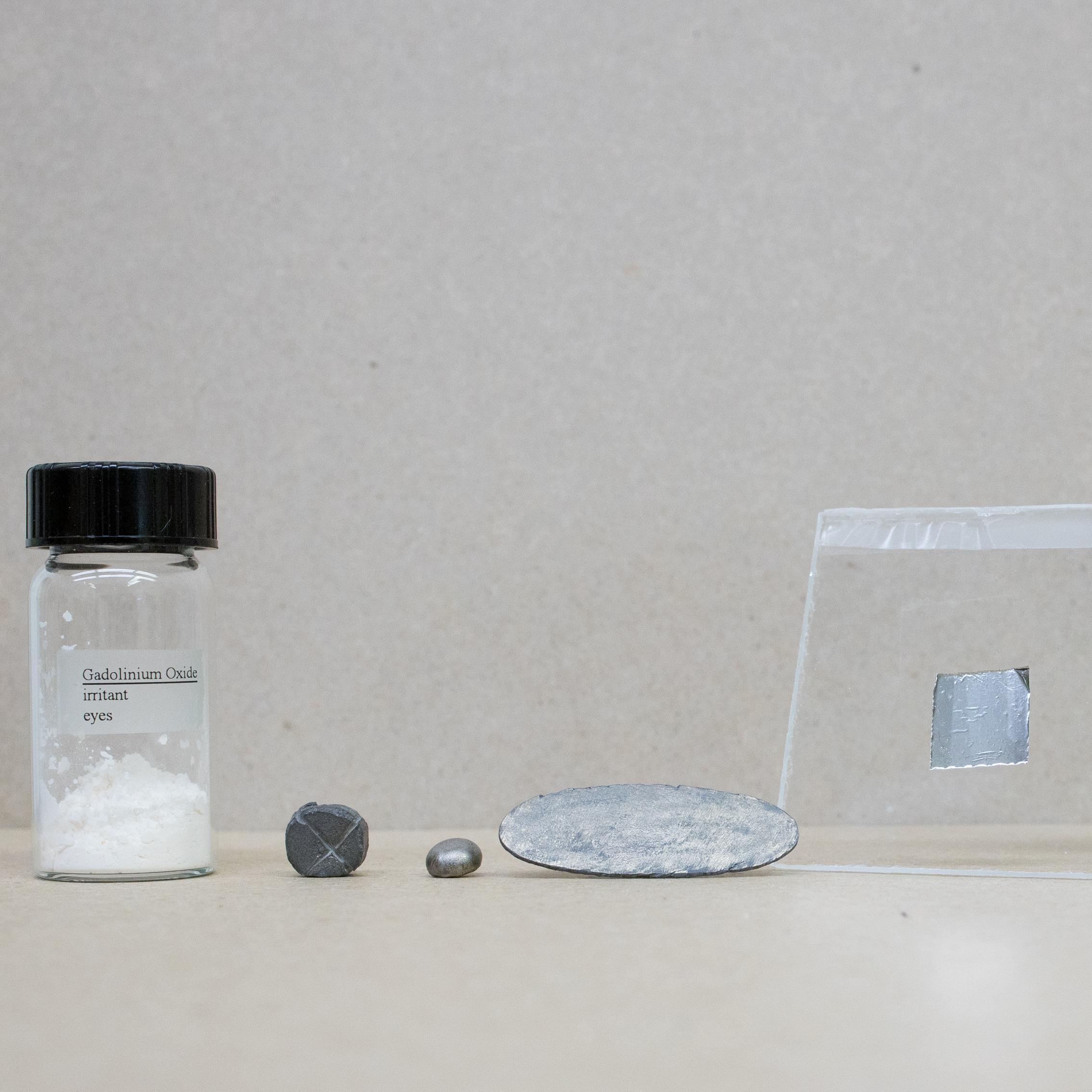

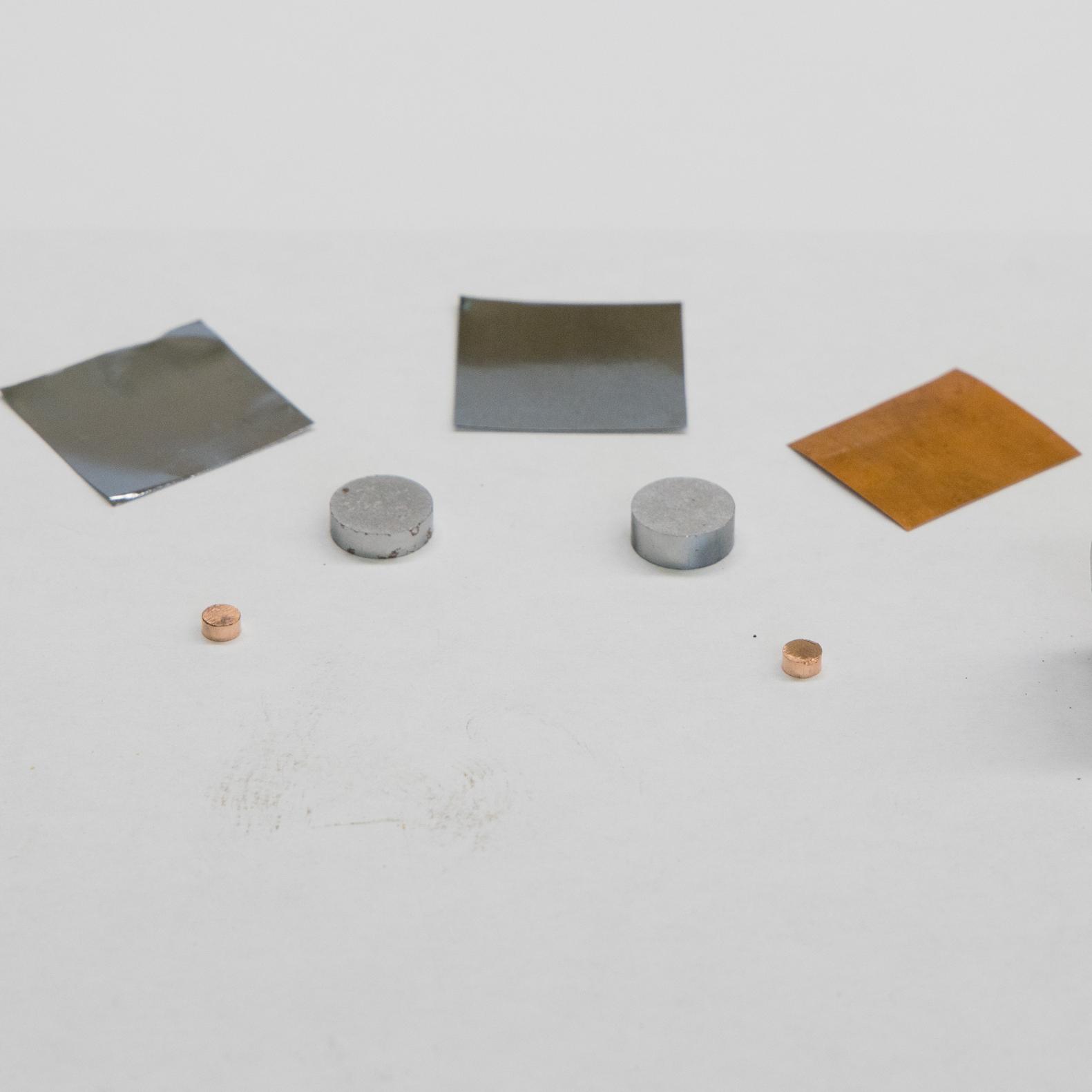

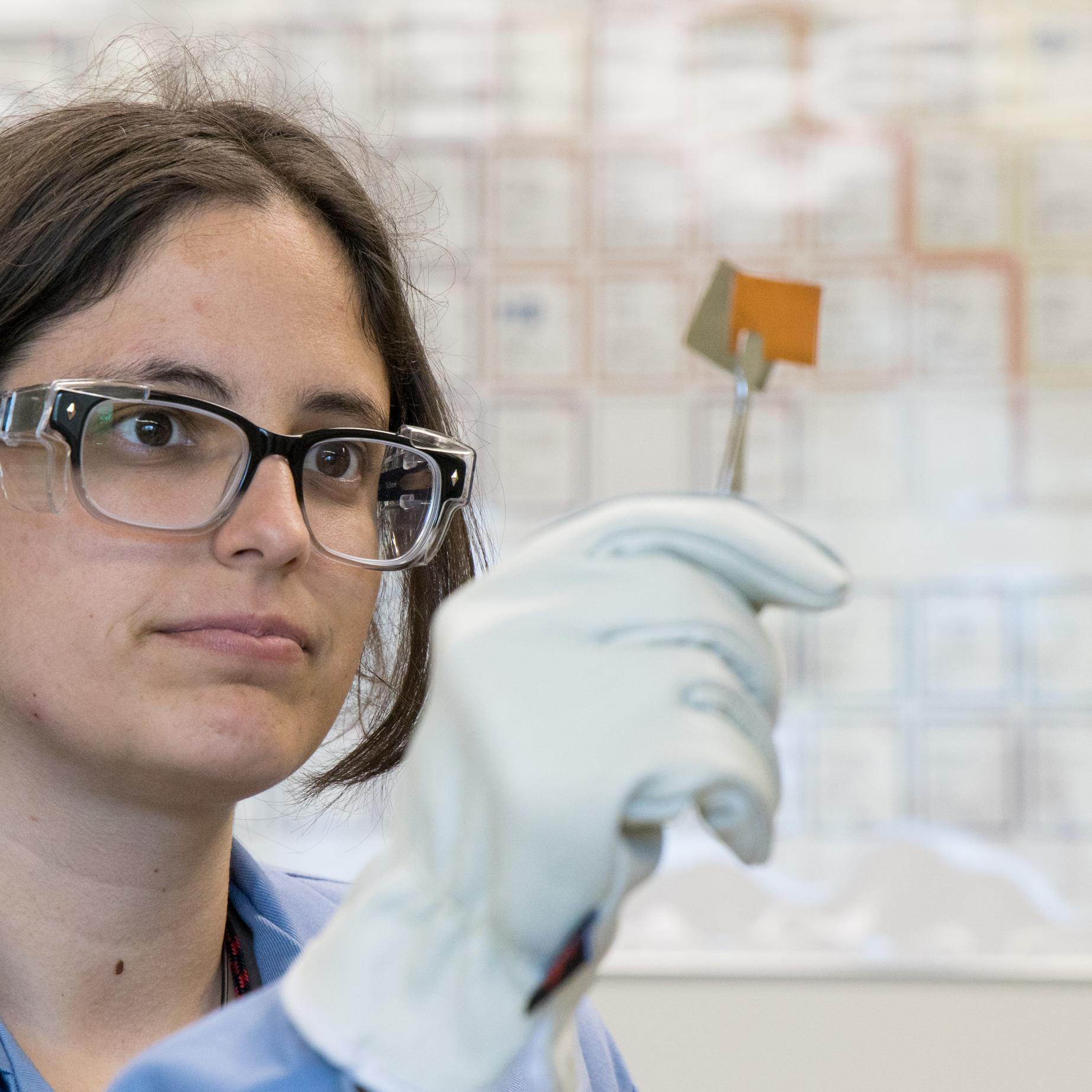

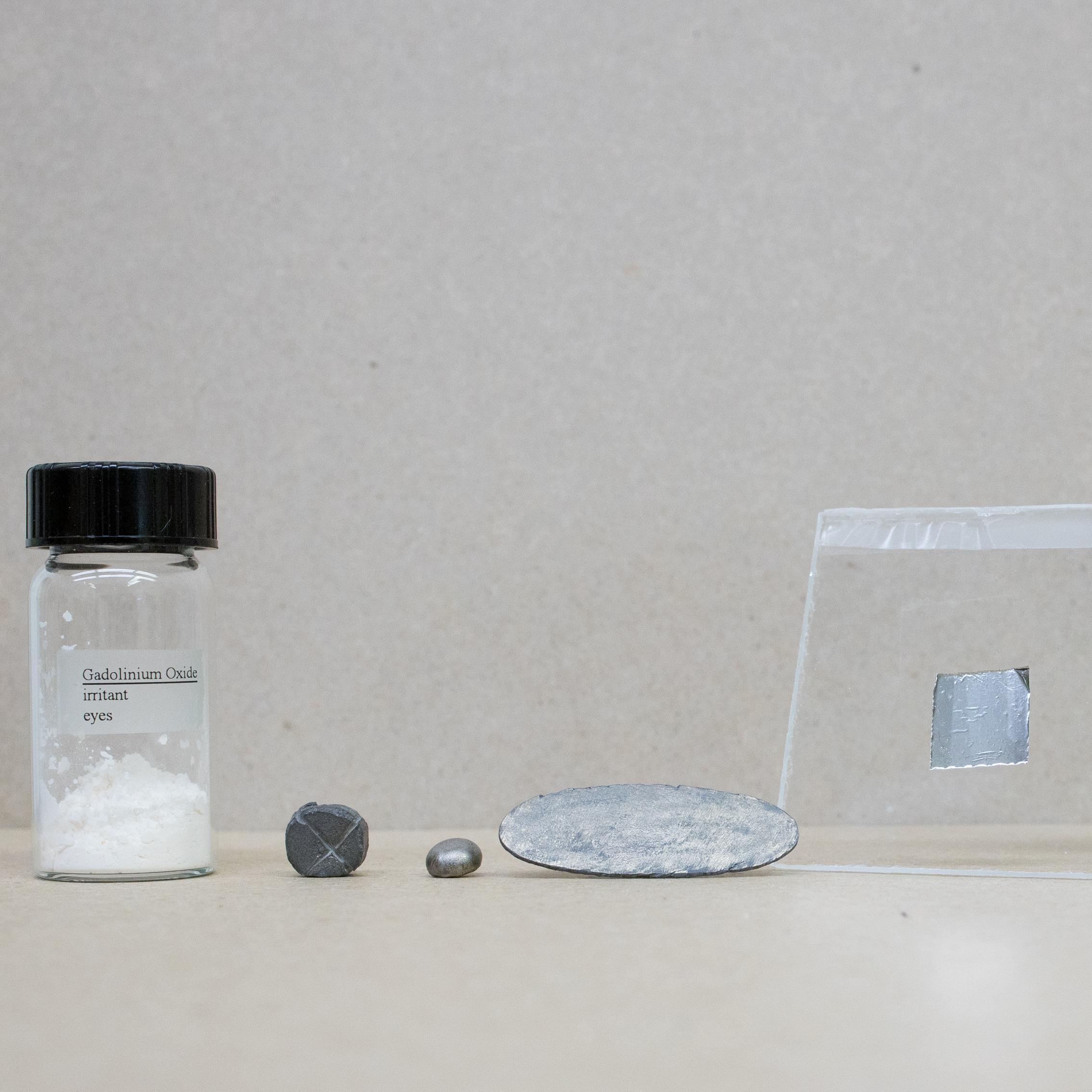

Custom targets

Various custom target forms can be fabricated such as foils, pellets, or and discs

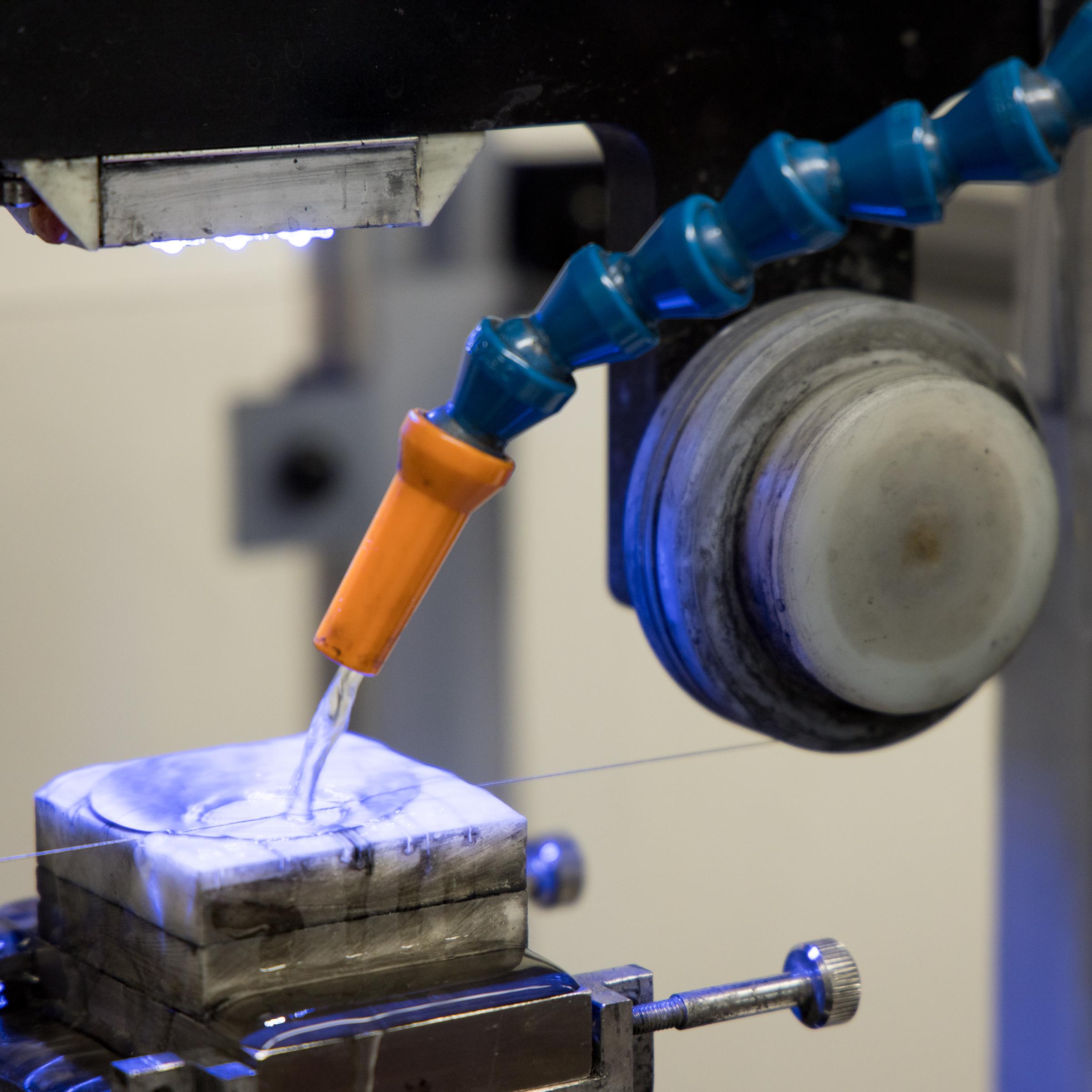

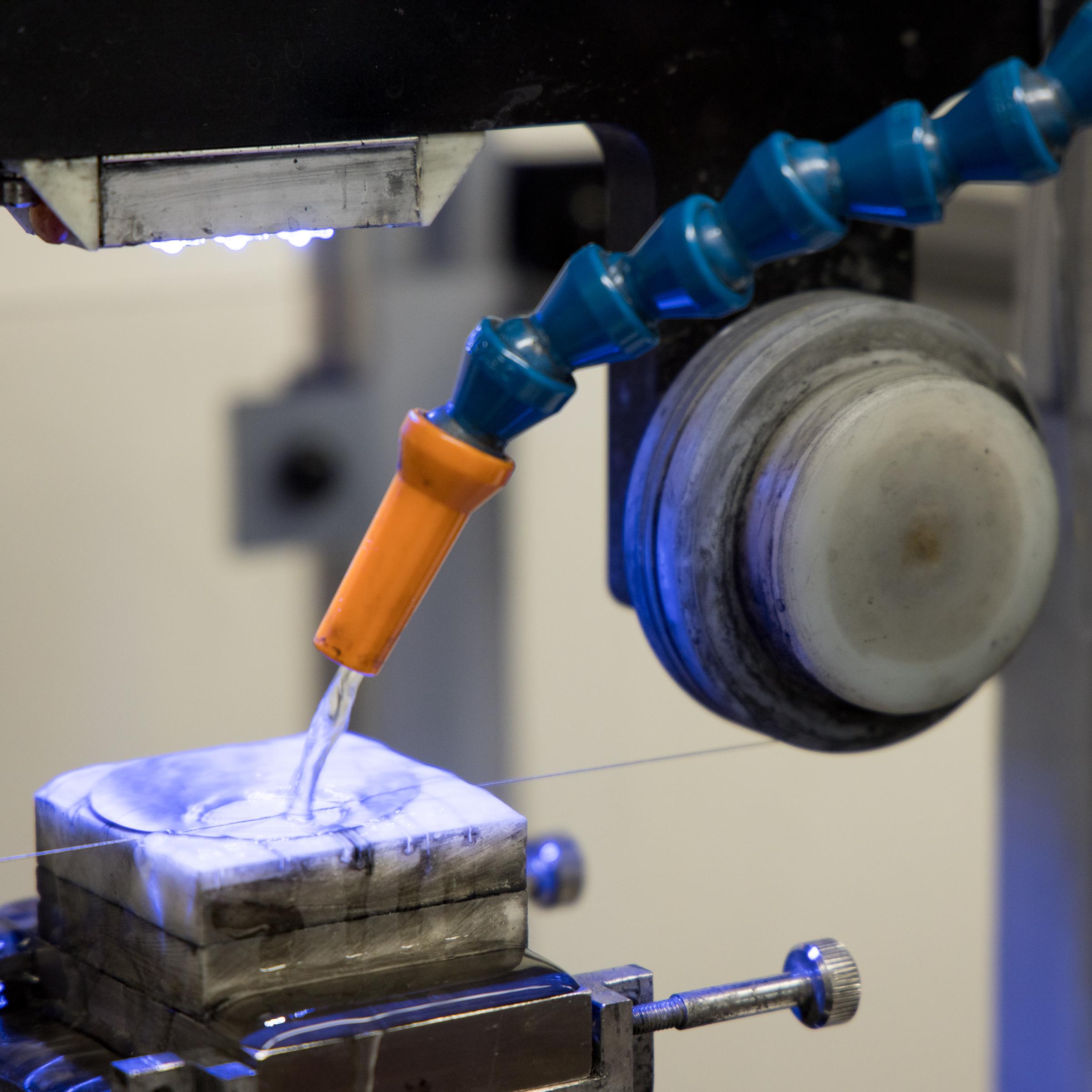

Diamond abrasive wire sawing

A technique used to cut materials with minimal losses

Enriched gases

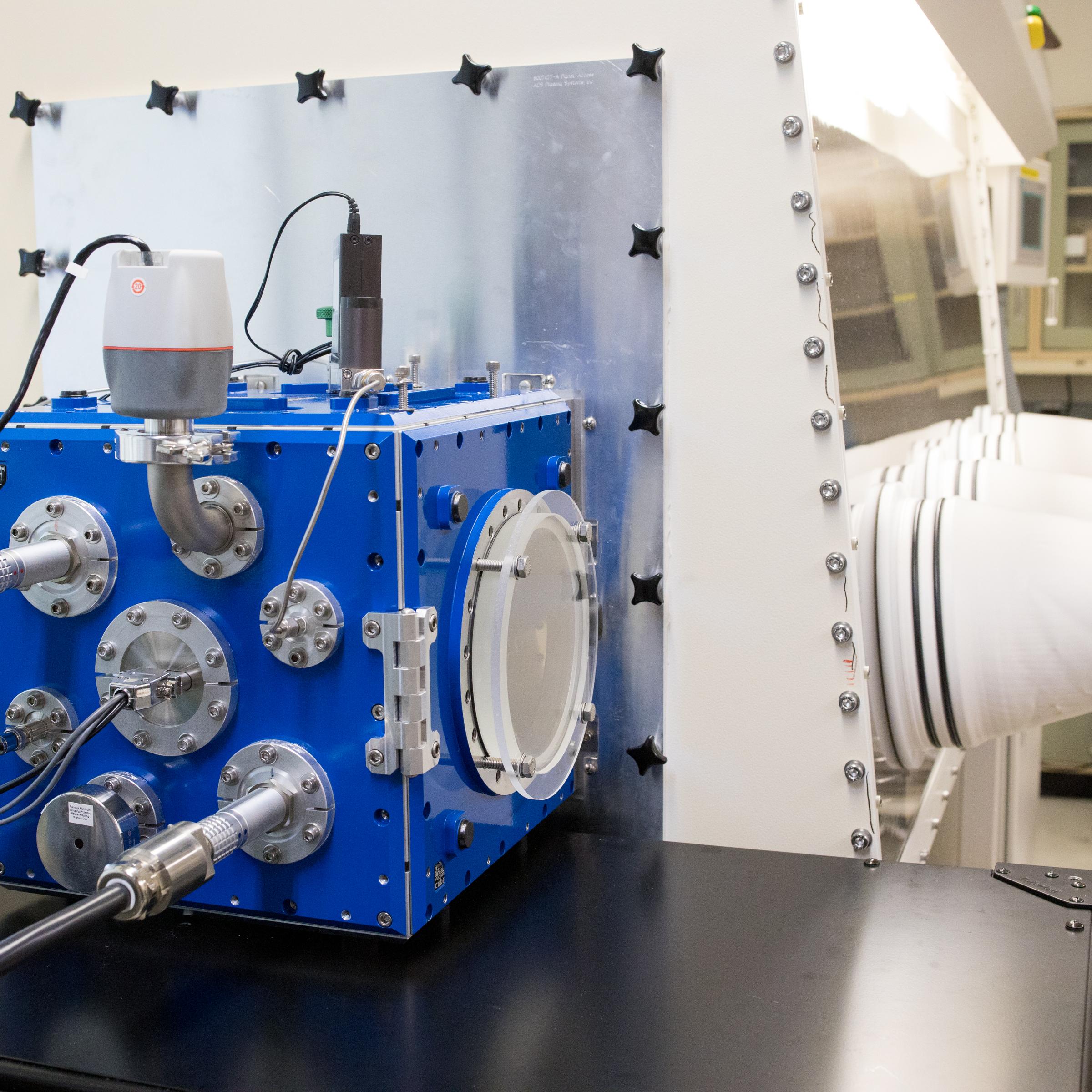

Transfer of high-purity enriched gases into small high-pressure cylinders

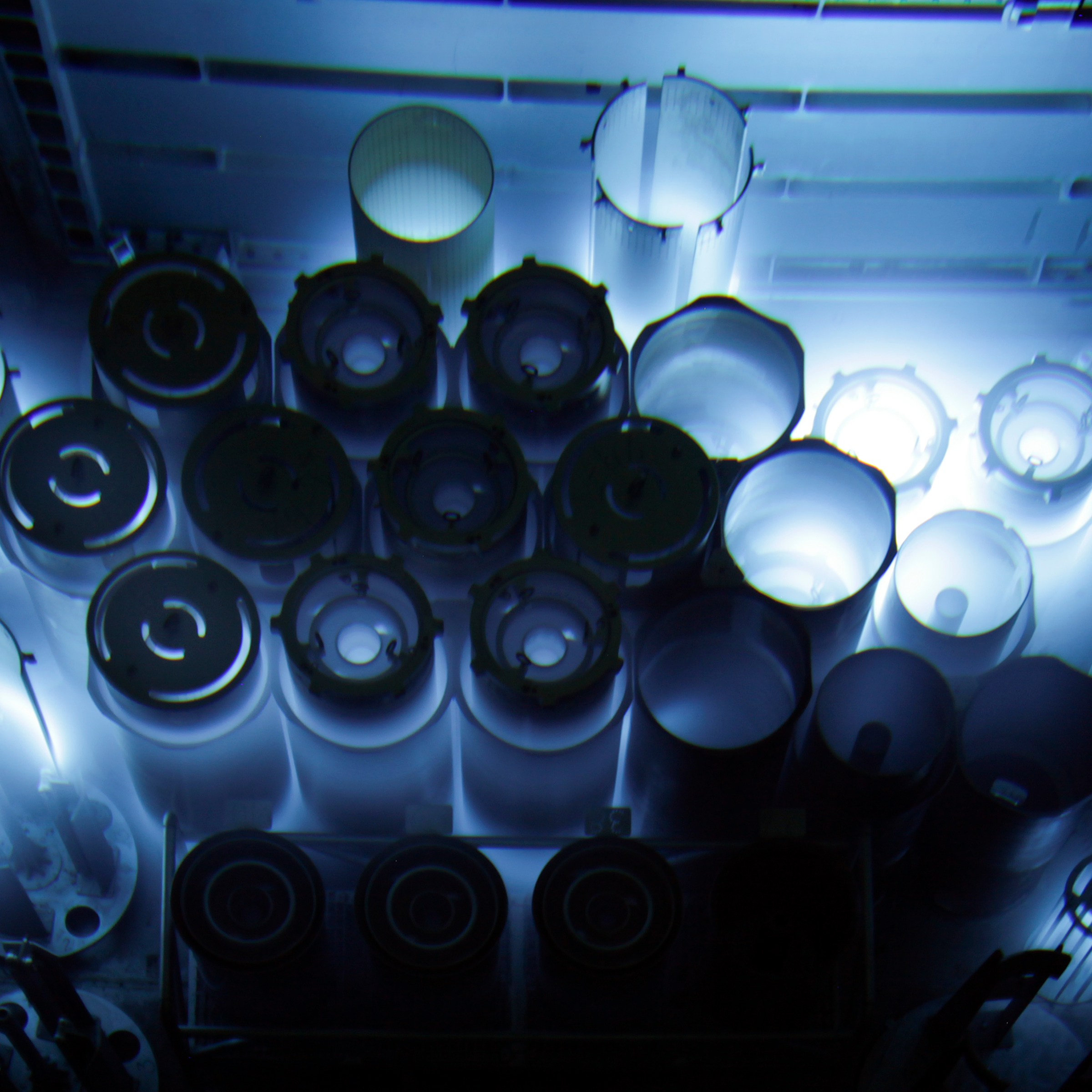

High vacuum evaporation

These techniques use resistance, Rf induction, or electron beam heating to prepare thin films and coatings from metals, oxides, and other compounds

Hot and cold rolling

Processes used to produce metal foils from the millimeter to micron thickness range

Inorganic compound synthesis, metallurgical, ceramic, and high-vacuum processing methods

Techniques used to process stable isotopes into the desired chemical or physical forms to meet customer needs

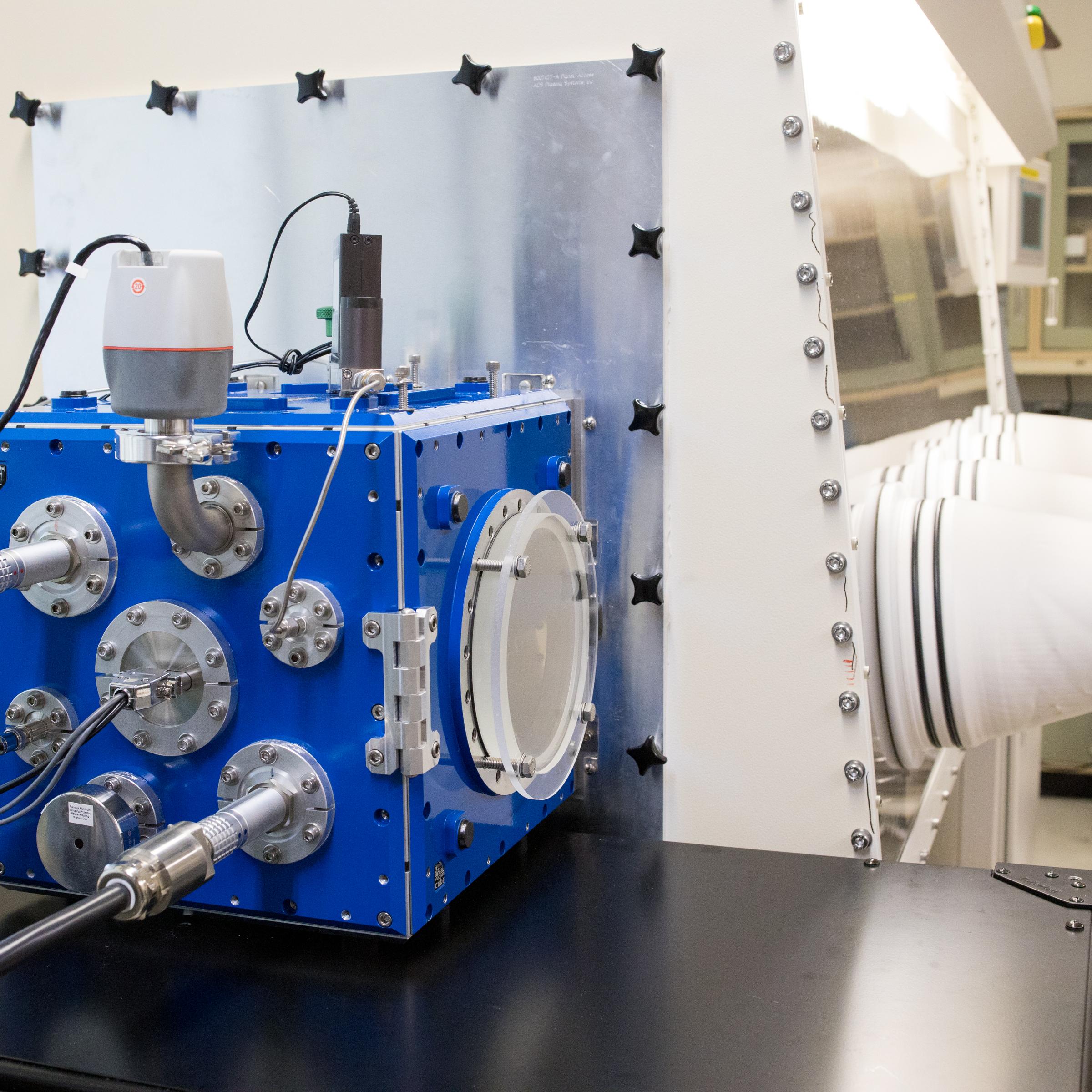

Ion beam and plasma sputtering

Processes used to produce thin films and coatings

Metal and ceramic powder consolidation techniques

Processes include cold pressing, sintering, and vacuum hot pressing

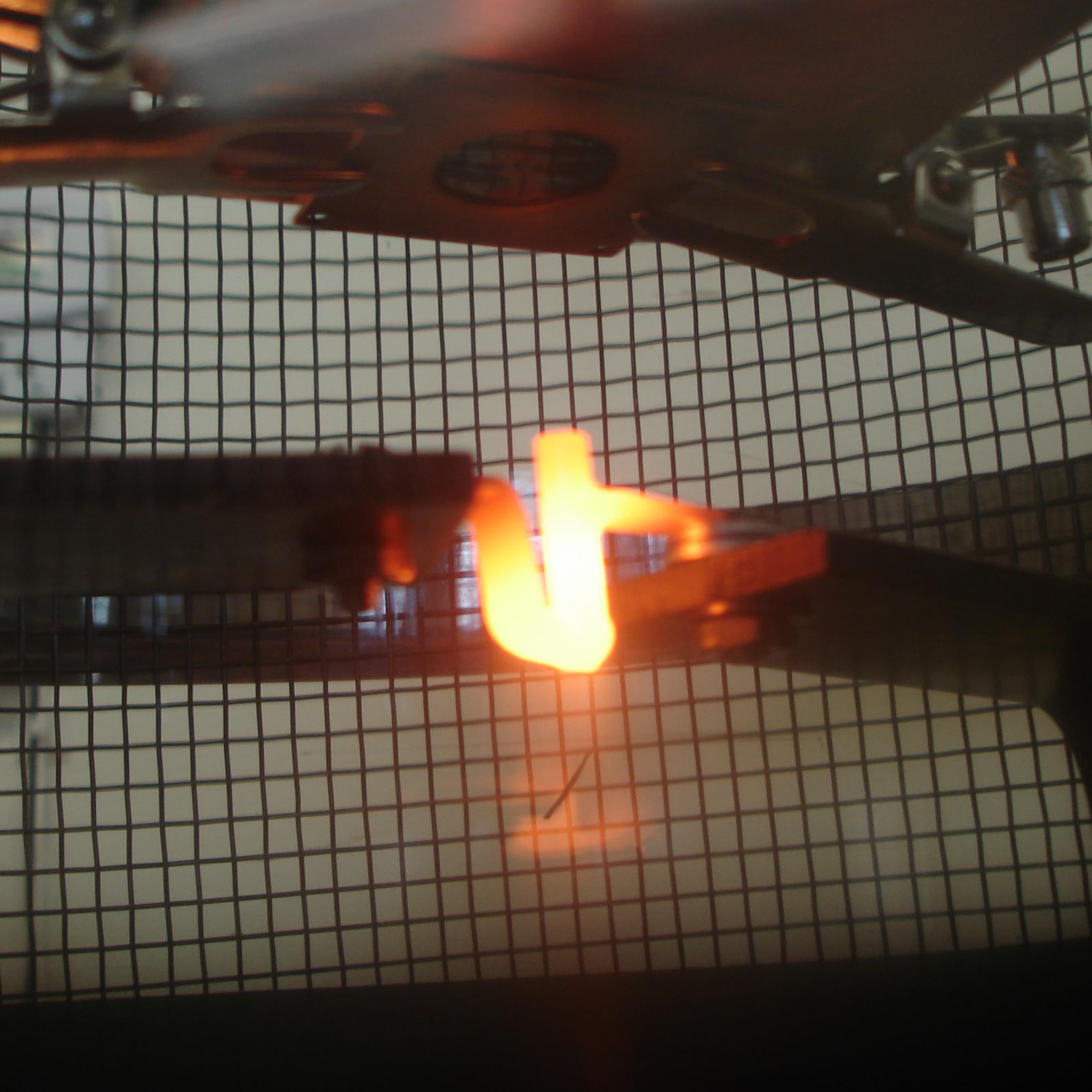

Pulse arc welding

This technique is used for joining metals

Pyrochemical conversion techniques

To convert rare earth and Group IIA elements from oxides to high purity metal via reduction/distillation

Wire casting, rolling, and swaging processes

These techniques are used to prepare metal rods and wires

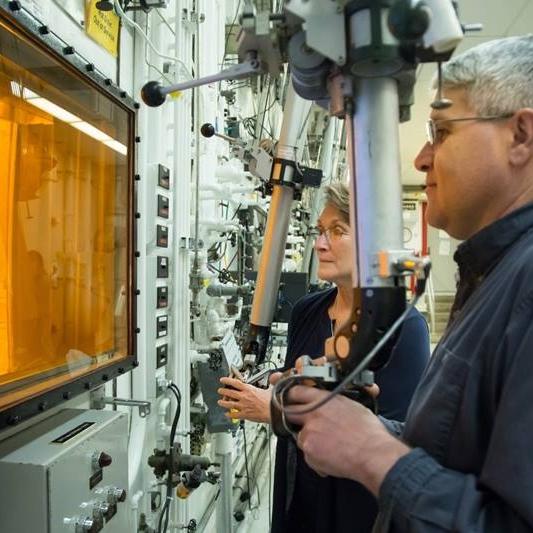

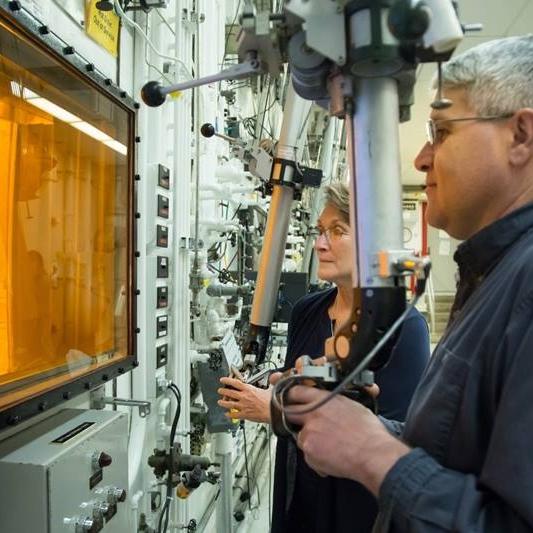

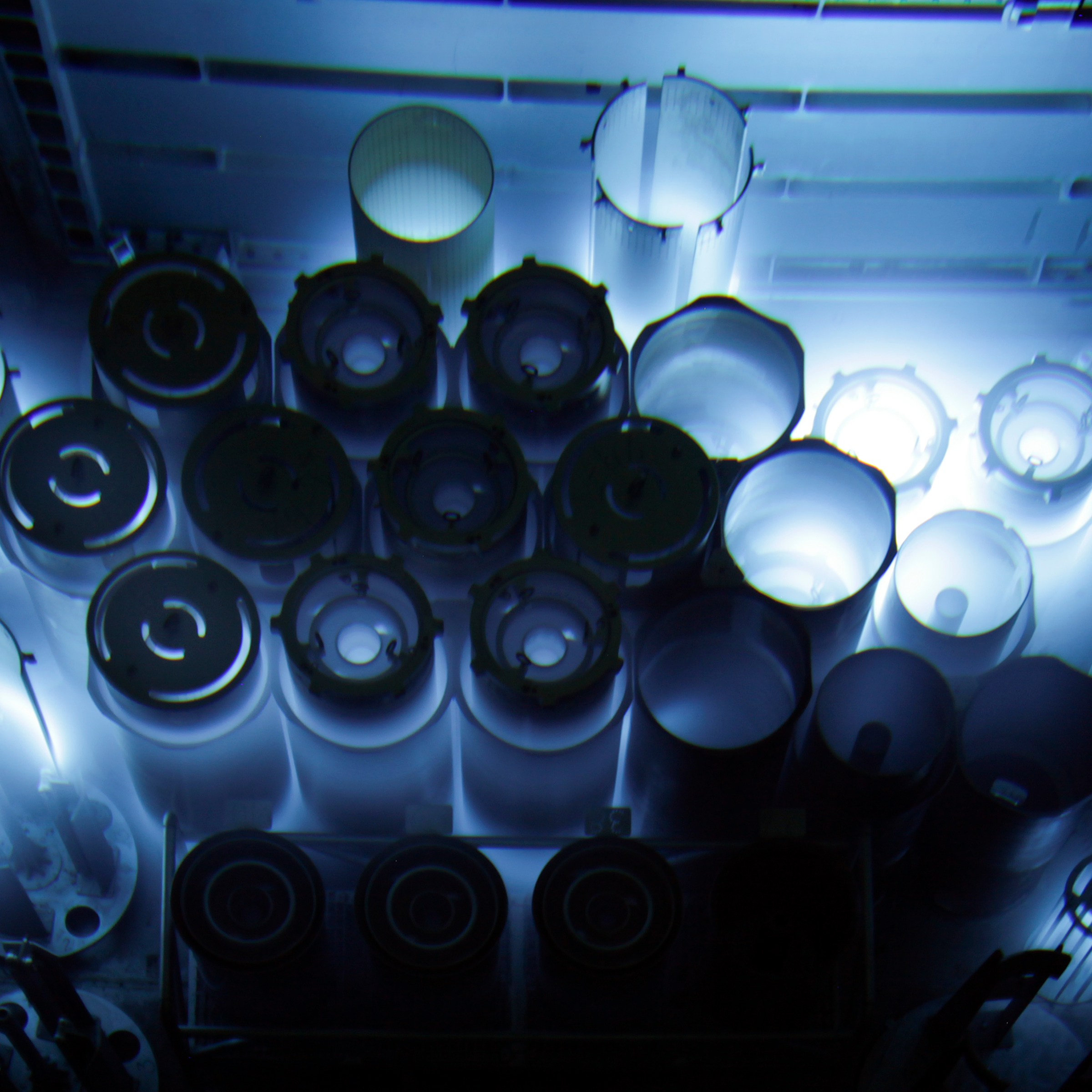

Radioactive Isotope Services (performed at ANL, BNL, LANL, and/or ORNL)

Custom chemical and physical forms

Preparation of a variety of radioisotopes may be possible

Nuclear medicine

Providing radioisotopes and support for the development of diagnostic and therapeutic radioisotopes and clinical trials

Target irradiations

Target irradiations may be supplied to the customer without processing